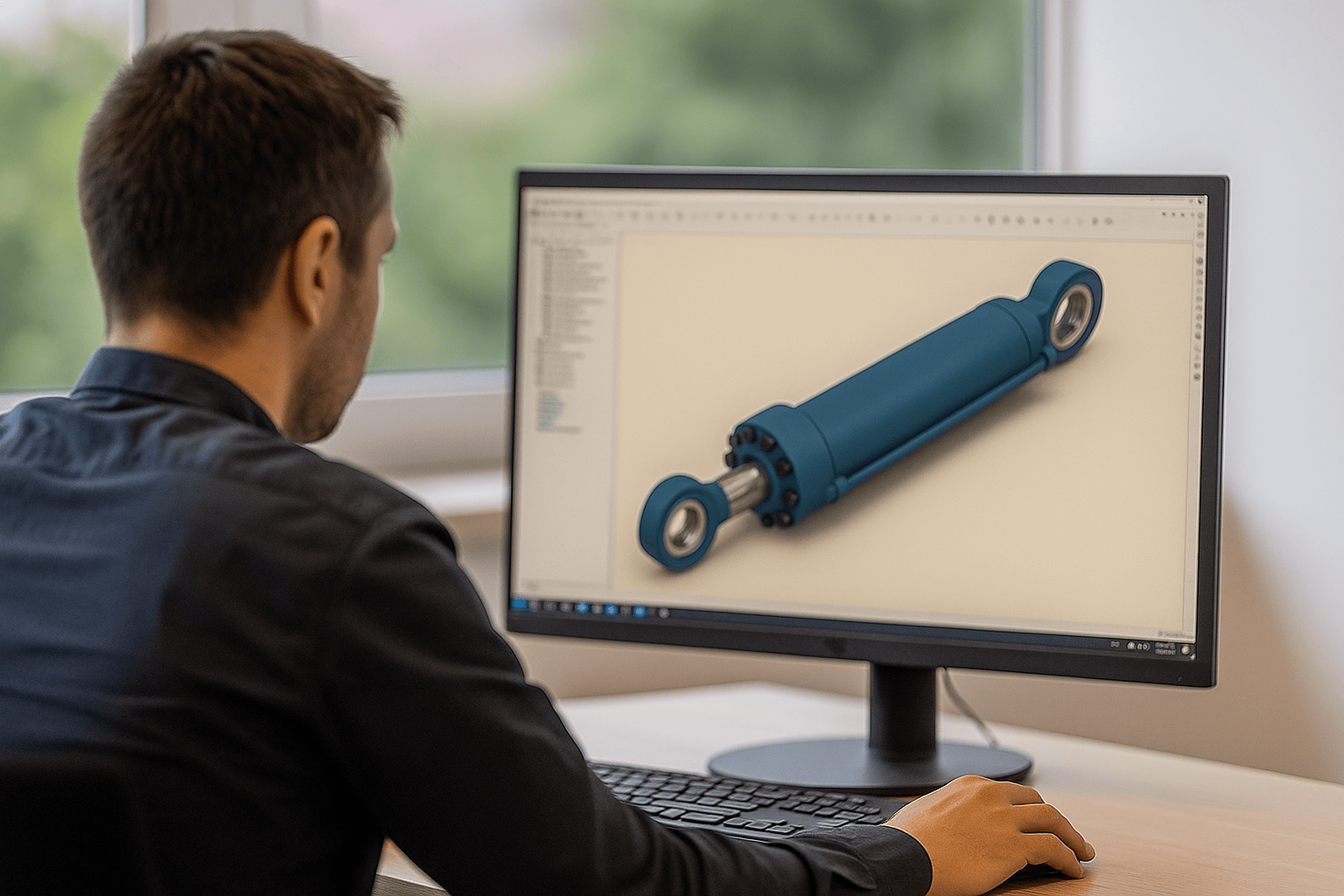

When it comes to hydraulic actuators, quality and performance are non-negotiable. They play a crucial role in various machinery's functionality, reliability, and efficiency, from construction equipment to forest machines. However, the quality of a hydraulic cylinder is not solely defined by its design or assembly; it is deeply rooted in the sourcing process behind the scenes - this is why our article explores the essential elements of effective sourcing in an own article.

Forecasting as a strategic driver of supply chain efficiency

A well-developed forecasting process is a cornerstone of effective sourcing and production planning at Norrhydro. With our advanced forecasting model, we gain enhanced visibility into resource requirements, production capacity, and procurement needs. This proactive approach enables accurate planning and timely decision-making across the supply chain. Importantly, it also keeps suppliers informed and aligned with Norrhydro’s future demand, ensuring they can respond promptly and effectively. As a result, delivery reliability is enhanced throughout the supply chain, ultimately benefiting our end customers.

Strategic sourcing – The key element in ensuring quality

The efficient sourcing phase lays the groundwork for hydraulic cylinder excellence. Norrhydro’s global supplier network, built on long-term partnerships and the selection of optimal materials and processes, is fundamental to delivering both product reliability and superior customer satisfaction.

Supply chain success starts with a reliable partner

At Norrhydro, we prioritise working with long-term partners who have a proven track record and who share our commitment to operational excellence, quality and sustainability. Our reliable industrial suppliers, supported by local quality control resources, ensure consistent material excellence, dependable delivery times and stable pricing. Strong supplier relationships also foster innovation, transparency, and faster problem-solving if issues arise.

Strengthening the supply chain through diversified sourcing

Norrhydro’s approach of engaging two or more qualified suppliers enhances our resilience to supply chain disruptions, such as raw material shortages, geopolitical uncertainties, or logistical challenges. This approach helps us to maintain production continuity and protects delivery commitments to our customers - risk management as we say.

High-quality materials with proven origins — The Norrhydro standard

Castings, forgings, seals, sensors and other components are all essential for hydraulic cylinders that must perform under high pressure—literally. Norrhydro has selected its suppliers based on their ability to confirm high-quality sources for materials and components that fully comply with strict industry standards and provide complete traceability. Substandard materials can compromise safety, reduce lifespan, and lead to costly field failures.

To support our customers’ sustainability goals, Norrhydro’s supplier network offers access to low-emission materials—such as low-emission steel— for customers seeking to reduce the carbon footprint of their final product. The use of low-emission materials also significantly reduces the carbon footprint of Norrhydro products.

SUBMIT YOUR COMMENT