High-performance Hydraulic Cylinders

With decades of experience, we specialise in developing and manufacturing premium-quality hydraulic cylinders according to diverse customer requirements across industries. Whether for material handling, forestry, or marine applications, our hydraulic cylinders are engineered to enhance efficiency and deliver reliable performance in demanding environments.

Hydraulic cylinder technical specifications

Cylinder customisation options & features

Hydraulic cylinder types

Norrhydro specialises in customer-specific hydraulic cylinders, including double-acting and multi-chamber types, which are sold directly to mobile machine manufacturers.

Accessories

Functionality and features of a cylinder can be enhanced with accessories such as integrated valves and sensors.

Standardised coating process for added performance

Automated painting with a customised program for each cylinder: C4 Medium class corrosion protection can be achieved with a single coat, while there is also the possibility for dual-layer coating compliant with the C5 High corrosion protection standard

Choosing the right hydraulic cylinder is not just about size or stroke — it’s about fit-for-purpose engineering:

- Operating pressure and load requirements

- Mounting configurations and space constraints

- Work cycle frequency and duty intensity

- Environmental exposure — water, dust, chemicals, vibration, cold or heat

- Integration with control systems and safety features

Thanks to our customer-oriented product development and standardised NPI process, we ensure your projects stay on schedule without compromising quality.

- Efficient supply chain – reliable suppliers for components

- Production planning – demand forecast to minimise delays

- Lean manufacturing to streamline production

- Quality control – ensuring quality at every stage of production to avoid rework or product rejection

- Proactive customer communication - about lead times and any potential delays

At Norrhydro, we manufacture custom hydraulic cylinders that combine superior quality, advanced engineering, and environmental responsibility.

Our production is based on a high recycling rate and responsible use of water and energy. We are committed to minimising our environmental footprint by channelling waste heat from production into the local district heating network, and part of our energy is generated from solar panels – a concrete step towards reducing CO₂ emissions and increasing the share of renewable energy in our operations. Read more about sustainability at Norrhydro.

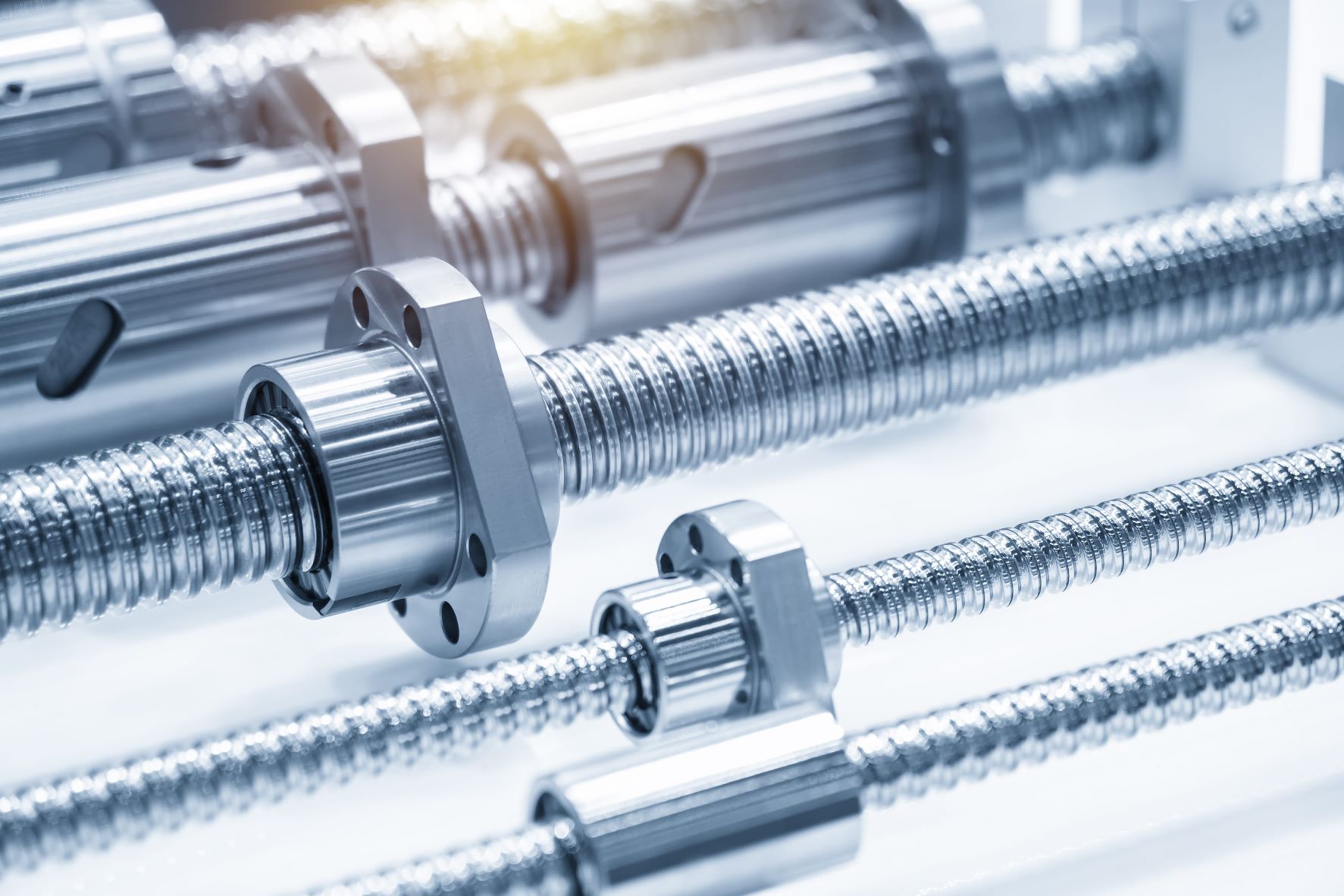

Key features of our production:

- Top-level hydraulics cleanliness throughout the whole process

- Latest production technology, incl. friction welding

- Flexible production capacity to support different volumes of our customers

- Improved production flow and lead time

- LEED certification

When you choose Norrhydro, you’re not only investing in a high-performance hydraulic solution – you’re choosing a partner who is building for a better tomorrow.

All hydraulic solutions are tailored to meet specific application requirements. While specifications are the starting point, our skilled engineers bring value-adding innovativeness to the table.

- Customer-oriented product development

- Standardised engineering process

- Design confirmed by FEM analysis and testing

- Lifetime product optimisation

How high-quality hydraulic cylinders are made?

Customer-oriented engineering

Standardised engineering process confirmed by FEM-analysis and testing for optimal lifetime.

Efficient procurement

Ensures consistent access to high-quality materials and components

Hydraulic cleanliness

Top-level hydraulics cleanliness throughout the whole process

Norrhydro Group Oyj

Headquarter & production

Ratavartijankatu 2

FI-96100 Rovaniemi, Finland

Product development

Raspinkatu 4

FI-33840 Tampere, Finland