In mining applications, equipment must operate reliably under continuous cycles and harsh working conditions, including limited maintenance windows and 24/7 usage. Norrhydro design and manufacture high-performance hydraulic cylinders for underground and surface mining machines, built to withstand extreme loads, abrasive conditions, and continuous operation. Engineered for reliability in demanding environments, our robust solutions—especially for mining loaders—minimise downtime, extend service life, and keep your machines running when it matters most.

Durability under extreme conditions

Corrosion and wear resistance:

- Piston rod plating corrosion resistance up to ISO 9227 NSS 1500 h R10

- Stainless duplex steel piston rods for ultimate corrosion resistance

- ISO 12944 Corrosion class C4M / C5M on request

- Hardened piston rods and optional rod guards to prevent damage from rock impacts

- Multi-stage sealing systems with heavy-duty seals

- Service-friendly cylinder designs

Safety functions:

- Integrated valves with optimised space utilisation

- Precise position sensing with embedded sensors

- End-of-stroke hydraulic cushioning

Environmental and sustainability requirements:

- Bio-oil compatible

- Option to use low-carbon-footprint steel-> reducing material-related CO2 emissions

Heavy-duty meets precision – from drill to dump

Cylinders for every motion:

- Drilling rig

- Steering

- Tilt & swing

- Feed

- Outriggers (integrated force measurement)

-

40 years of experience in hydraulics

-

Proven know-how of the mining segment

-

Custom-engineered solutions

-

High R&D rate

-

High reliability & long service life

-

Smart & service-friendly design

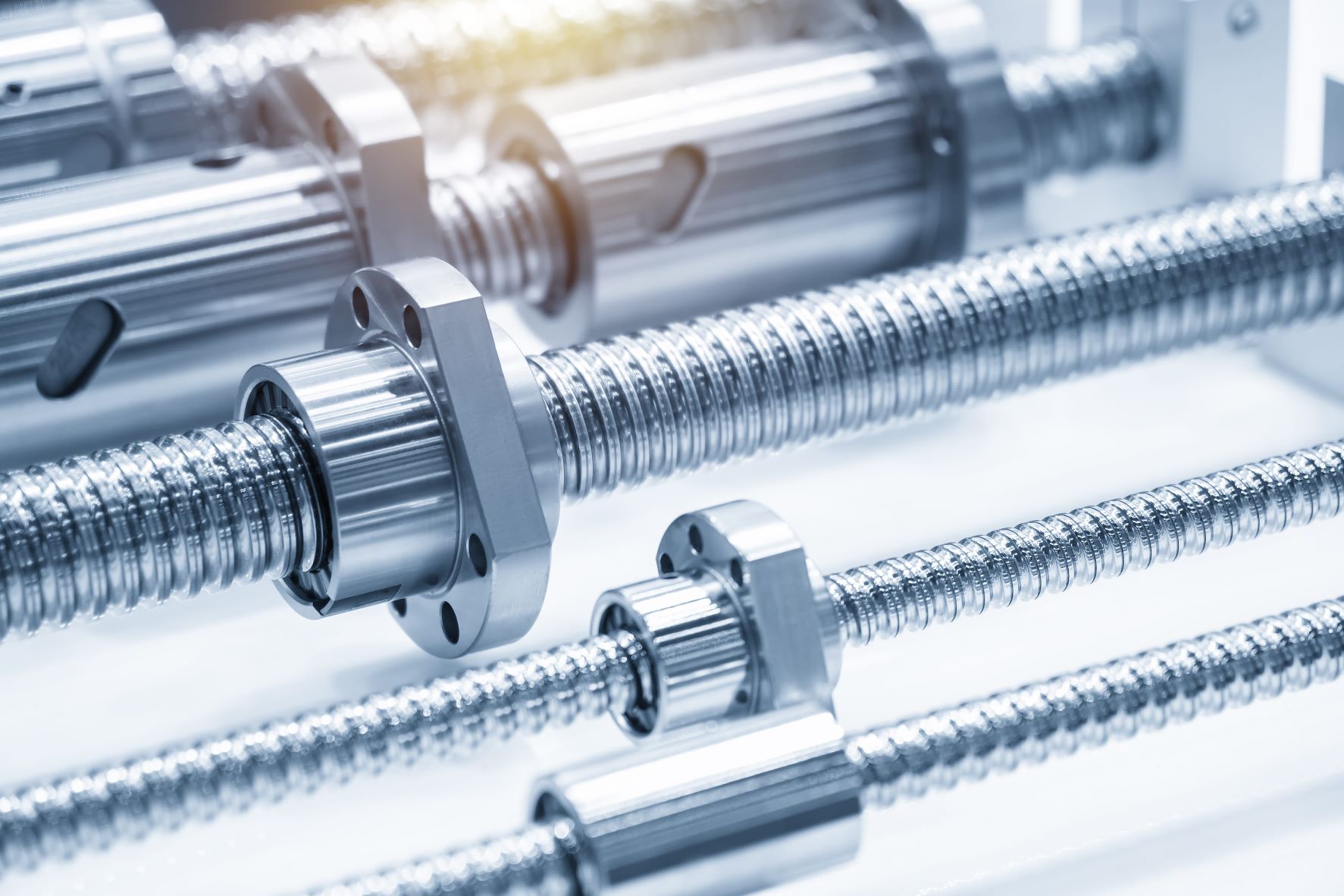

How high-quality hydraulic cylinders are made?

Customer-oriented engineering

Standardised engineering process confirmed by FEM-analysis and testing for optimal lifetime.

Efficient procurement

Ensures consistent access to high-quality materials and components

Hydraulic cleanliness

Top-level hydraulics cleanliness throughout the whole process

Norrhydro Group Oyj

Headquarter & production

Ratavartijankatu 2

FI-96100 Rovaniemi, Finland

Product development

Raspinkatu 4

FI-33840 Tampere, Finland