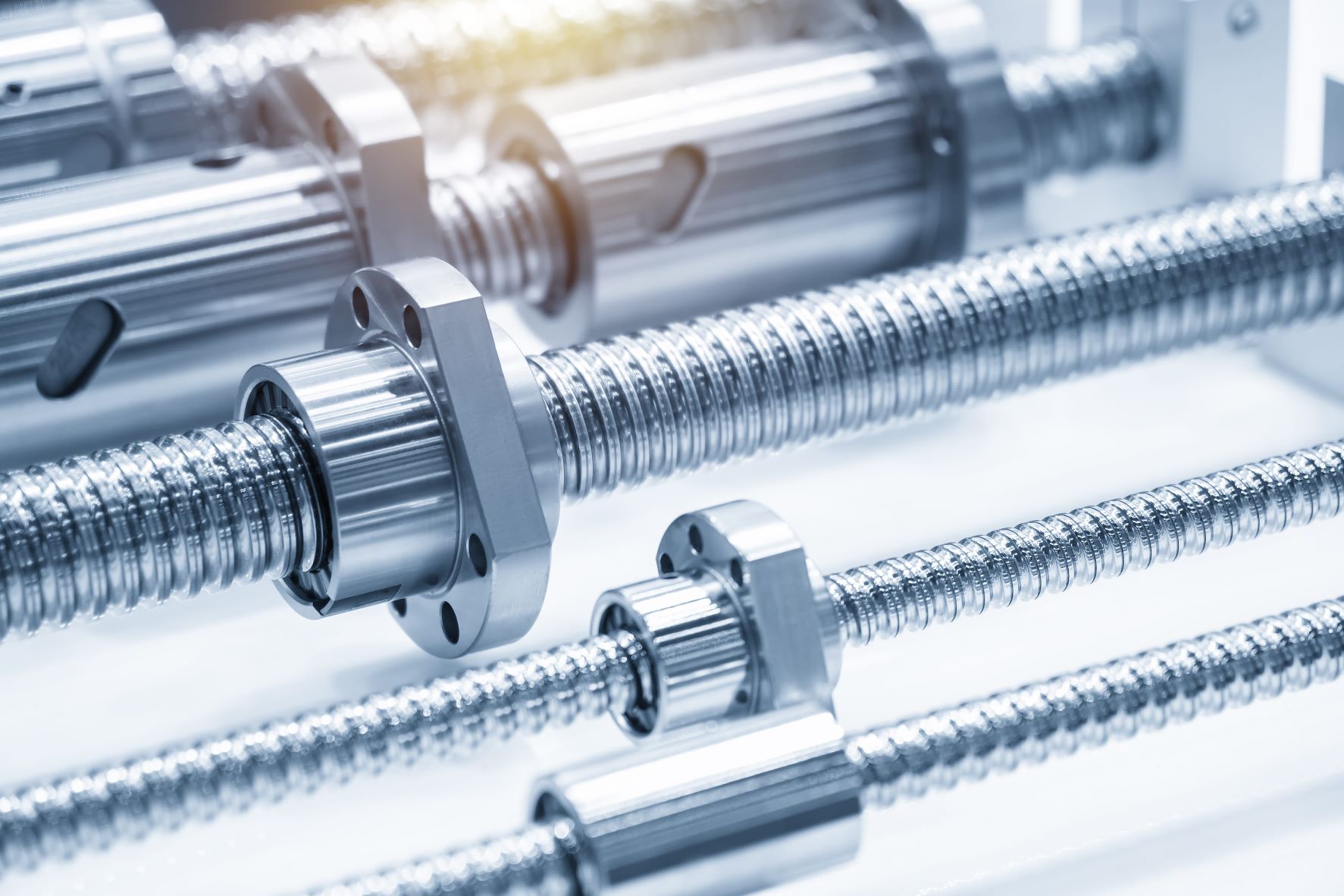

When it comes to material handling machinery, performance, safety, and durability are non-negotiable, while energy efficiency also plays an increasingly critical role. At Norrhydro, we design and manufacture high-performance hydraulic cylinders engineered to meet the demands of heavy-duty lifting, precise positioning, and repetitive high-force cycles in some of the world’s most demanding conditions. Deep R&D cooperation within this segment has resulted in remarkable energy savings

- Continuous quality control for the cylinder tube surface

- Verified fatigue calculations and optimised structural design

- Heavy-duty seals, piston rod wiper for extreme conditions

- Minimised downtime through extended service intervals

Environmental and sustainability requirements:

- ISO 12944 Corrosion classification C4M, C5M by request

- ISO 9227 Piston rod corrosion resistance up to: NSS1000 R10

- Cold-resistant sealing option (down to -40 °C)

- Bio-oil compliant

- Option to use low-carbon footprint steel -> reducing material-related CO2 emissions

Power, precision and reliability – Cylinders built for heavy handling

From lift to load - Tailored solutions for every motion:

- Boom

- Steering

- Locking

- Grapple

- Outriggers

- Cabin lift (option for electric actuator)

How high-quality hydraulic cylinders are made?

Customer-oriented engineering

Standardised engineering process confirmed by FEM-analysis and testing for optimal lifetime.

Efficient procurement

Ensures consistent access to high-quality materials and components

Hydraulic cleanliness

Top-level hydraulics cleanliness throughout the whole process

Norrhydro Group Oyj

Headquarter & production

Ratavartijankatu 2

FI-96100 Rovaniemi, Finland

Product development

Raspinkatu 4

FI-33840 Tampere, Finland